Products 레이저 미세가공 서비스

Polymer

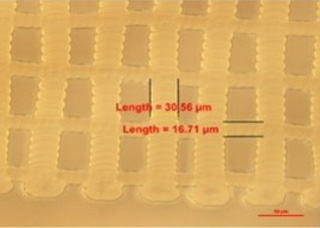

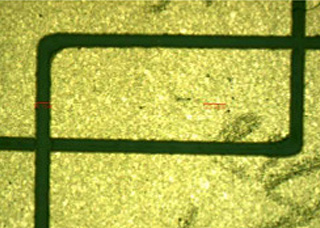

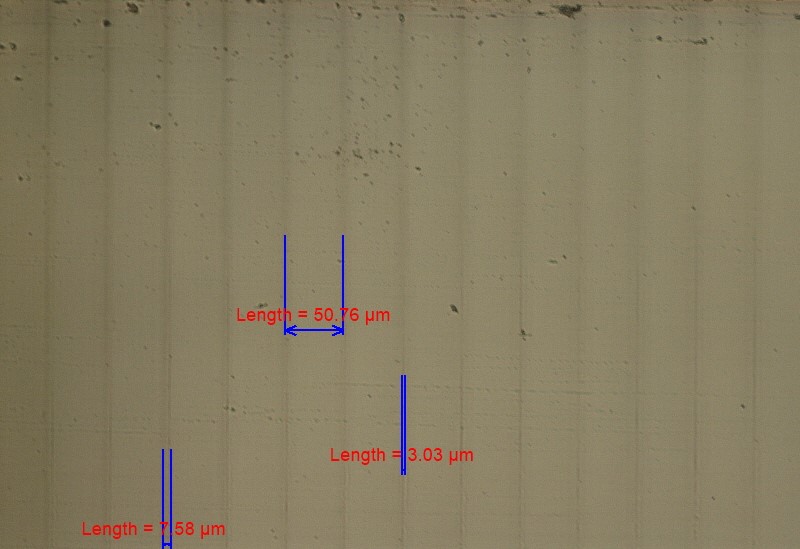

PET Film

Wavelength : 355nm

PET Film

Wavelength : 355nm

FTO Release (FTO on glass)

Wavelength : 355nm

Polyimide Film

Wavelength : 532nm

Polyimide Film Cutting

Wavelength : 355nm

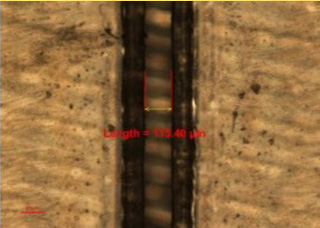

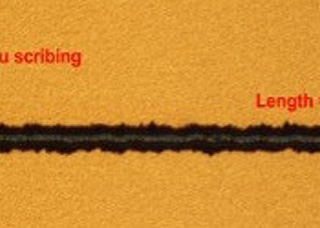

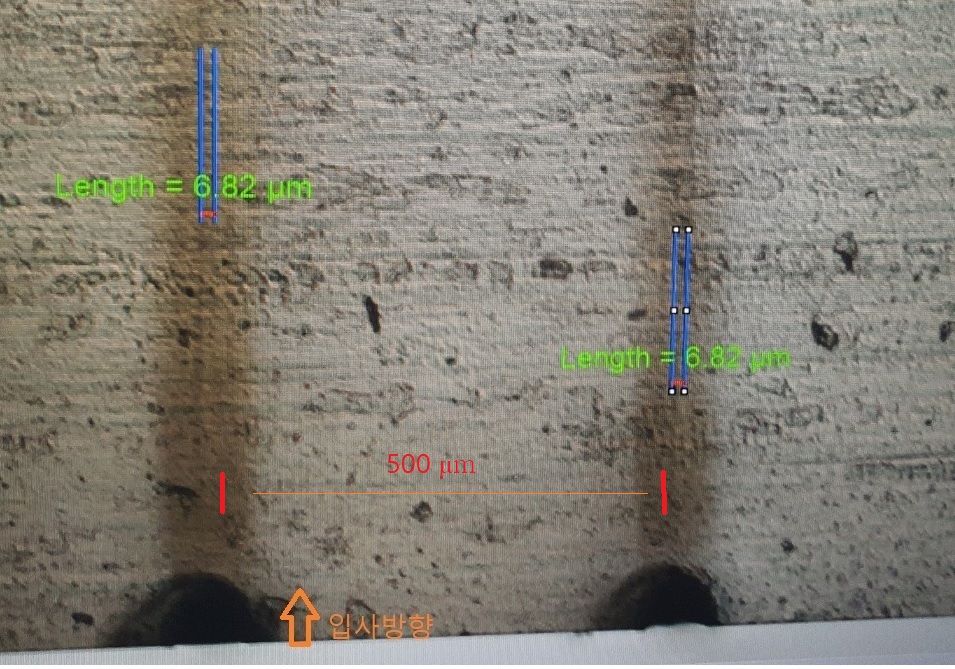

ITO Scribing (Including Ag)

Wavelength : 355nm

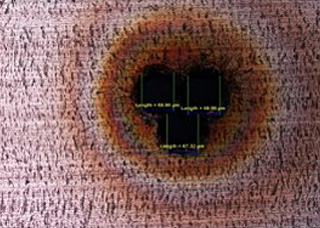

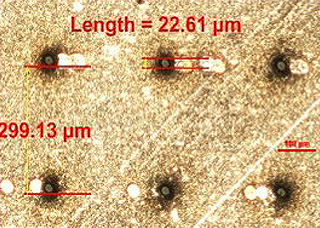

Hole Drilling

Wavelength : 355nm

Thickness : 2.8nm

Polaroid Film Patterning

Wavelength : 355nm

IRO Scribing (Ag Including)

Wavelength : 355nm

PET Film

Wavelength : 10.6µm

PET Easy Cut

Wavelength : 355nm

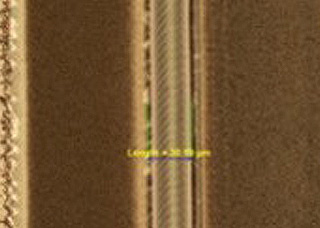

ITO Patterning (on the PET film)

Wavelength : 355nm

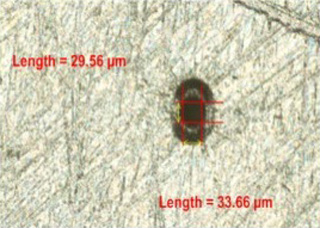

PI Film Circle Cutting

Wavelength : 355nm

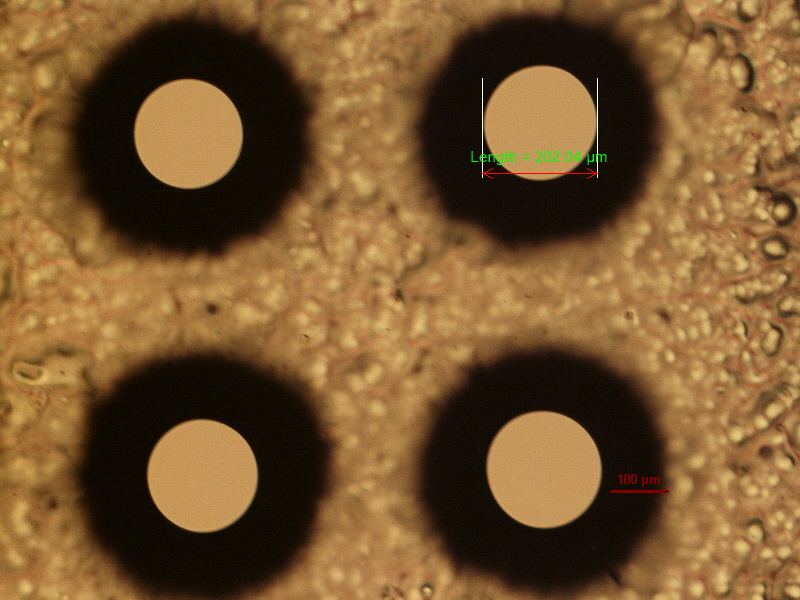

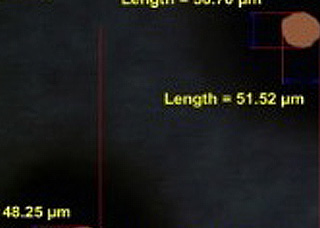

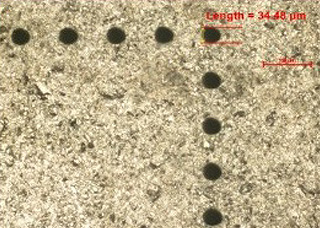

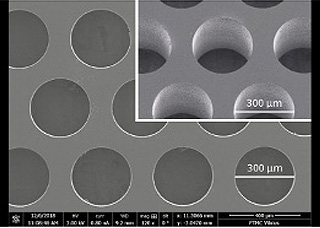

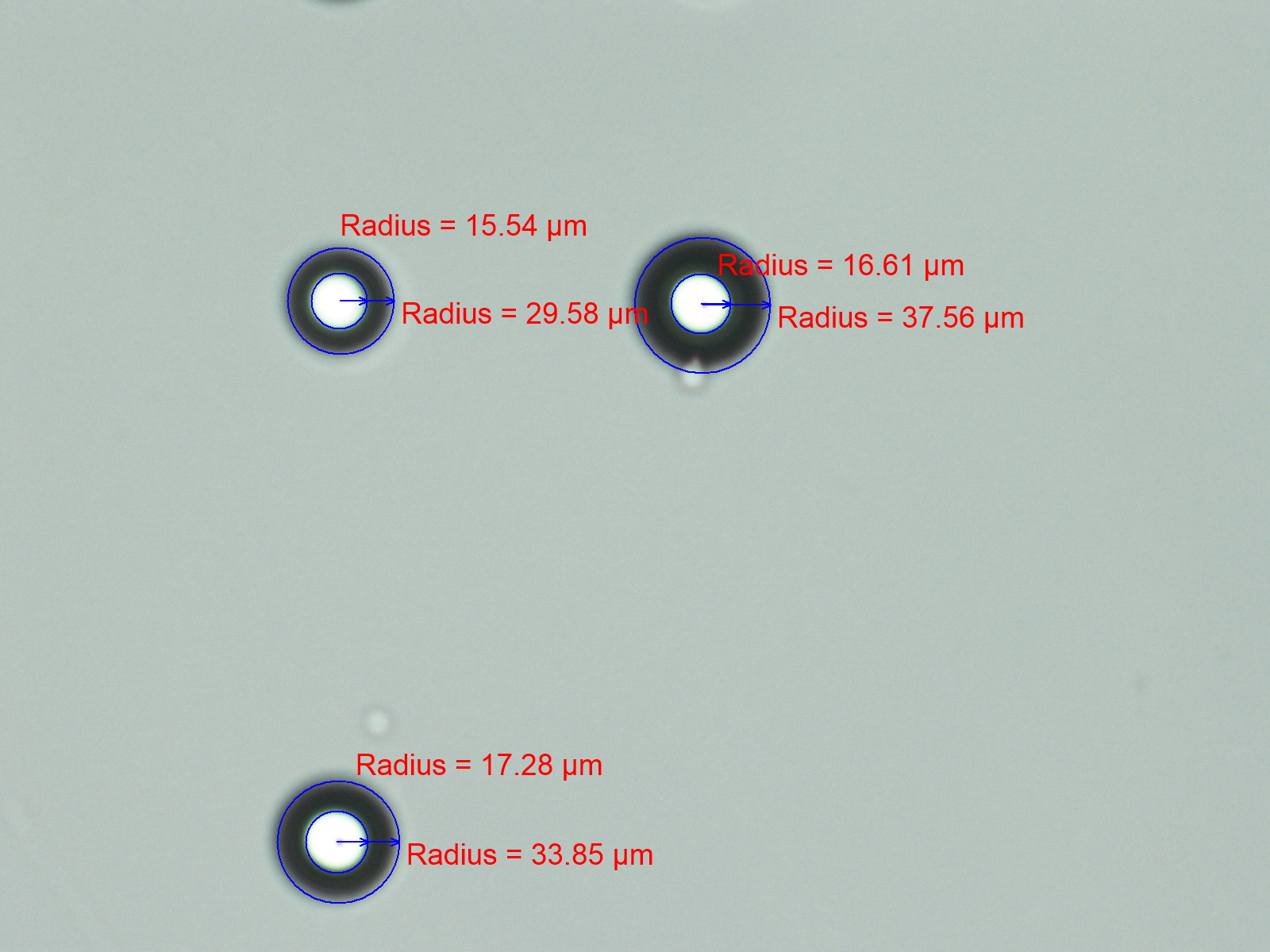

PI Film Circle drilling hole 1

Wavelength : 355nm(Pico seconds laser UV)

Thickness : 300μm

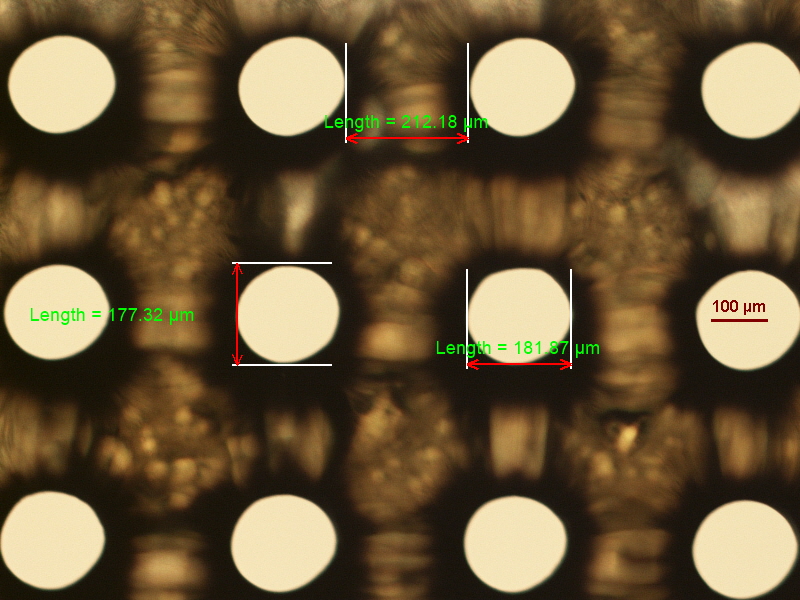

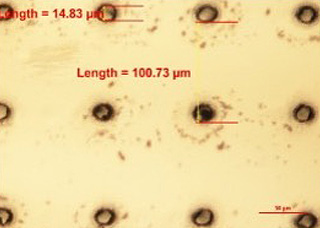

PI Film Circle drilling hole 2

Wavelength : 355nm(Pico seconds laser UV)

Thickness : 300μm

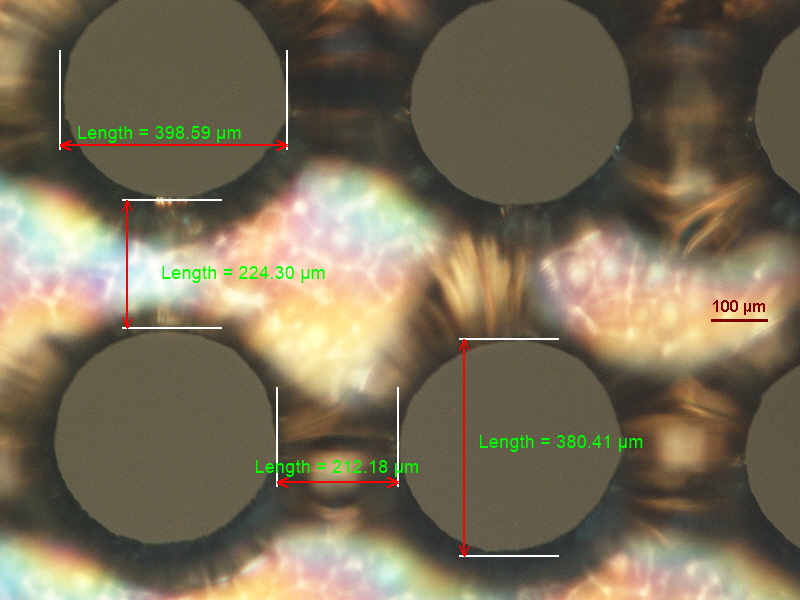

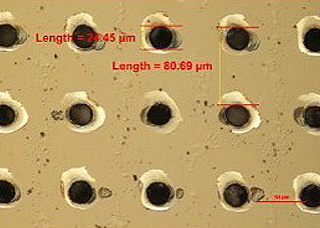

PI Film Circle drilling hole 3

Wavelength : 355nm(Pico seconds laser UV)

Thickness : 300μm

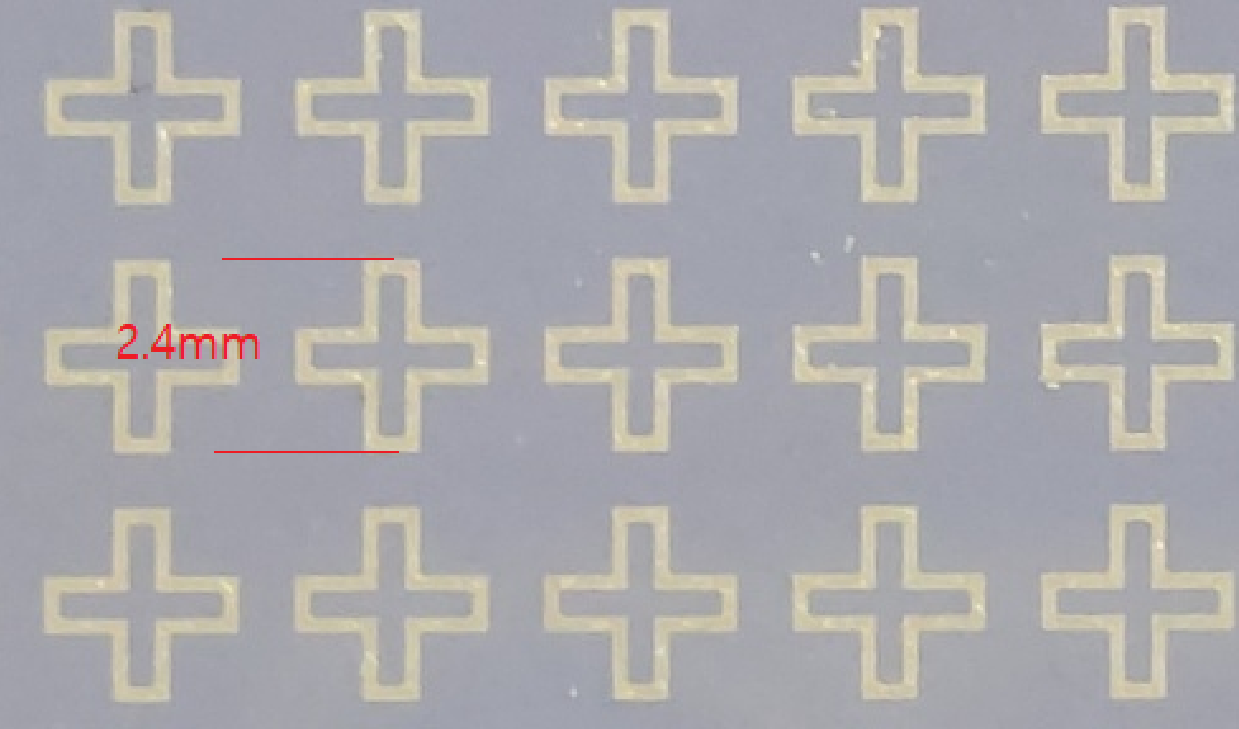

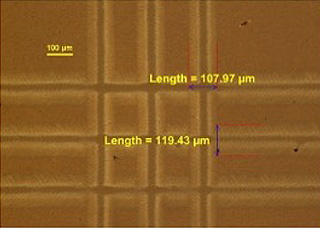

ITO Film Cross Patterning

Wavelength : 355nm

Thickness : 150nm

Wafer

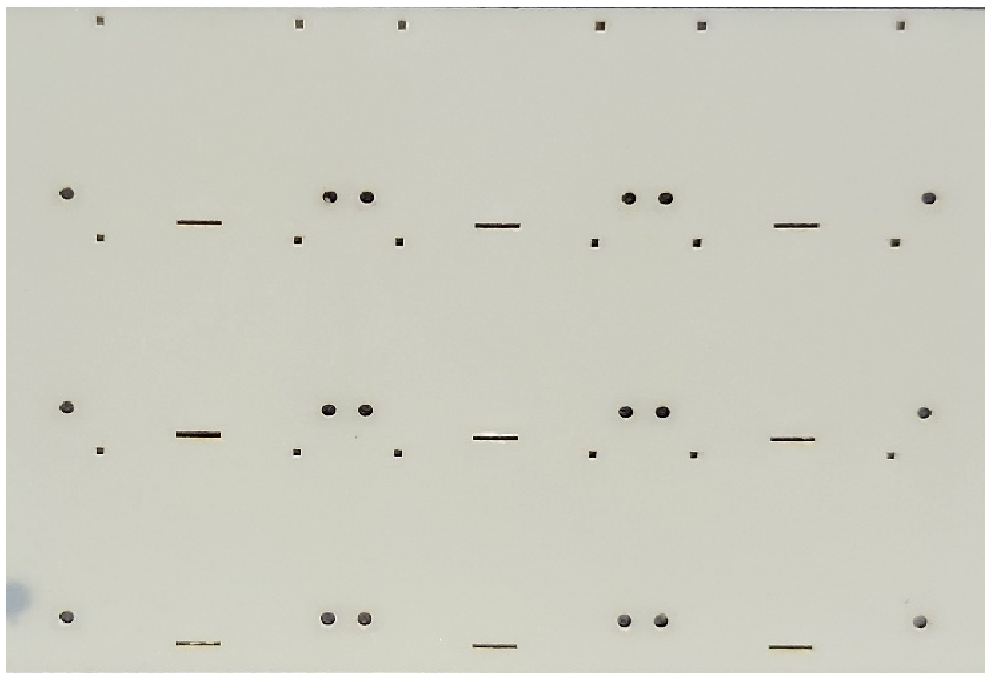

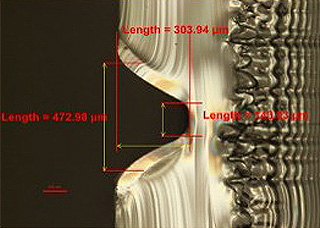

Drilling of Si-Wafer

Wavelength : 1064nm

Pulse energy :

Rep rate : 10kHz

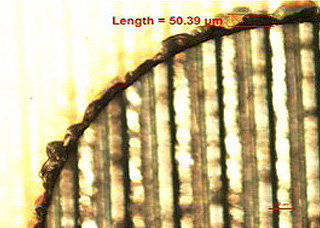

Si Wafer Round Cutting

Wavelength : 532nm

Thickness : 520μm

Edge Isolation of Si Solarcell

Wavelength : 1064nm

Pulse energy :

Rep rate : 500kHz

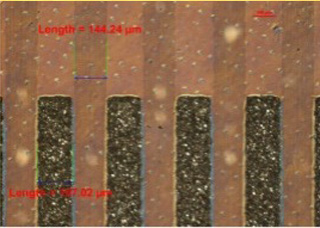

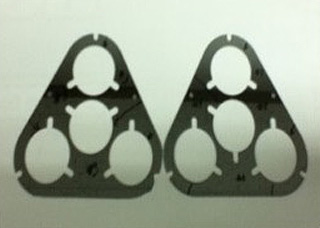

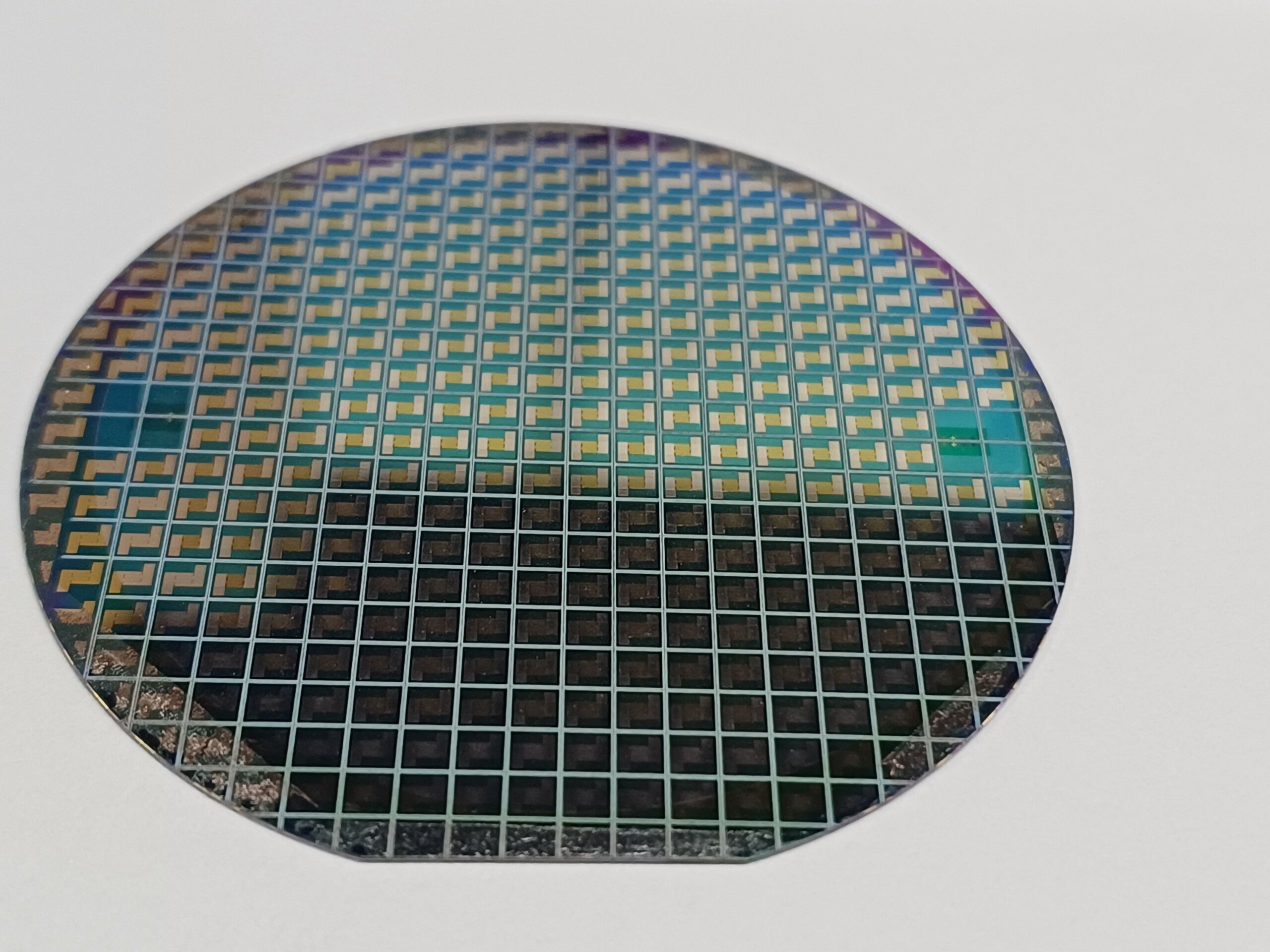

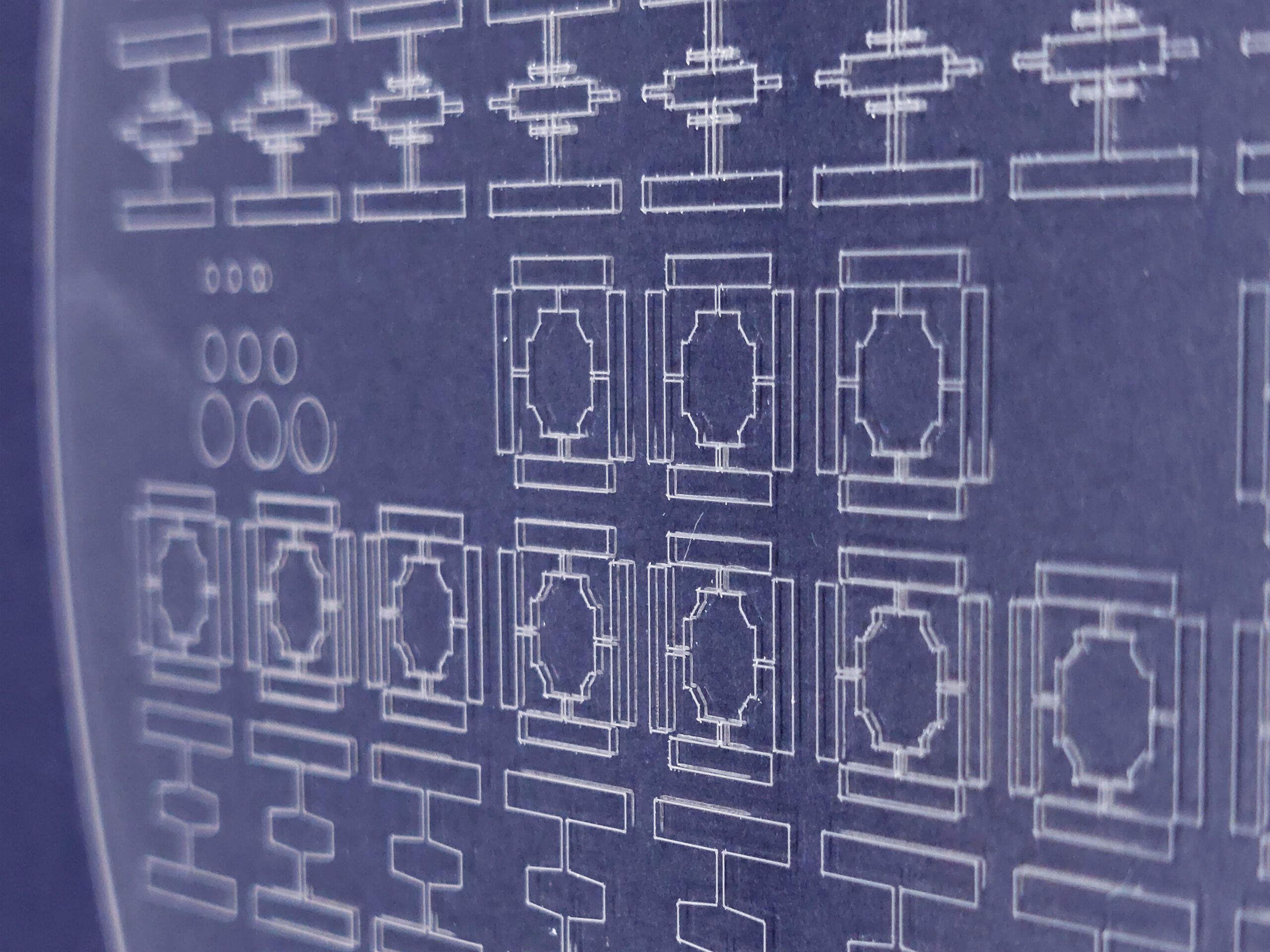

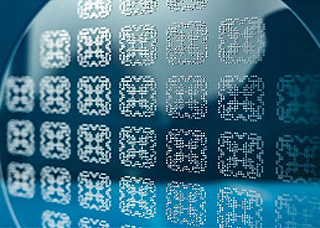

Si Wafer Pattern Cutting

Wavelength : 532nm

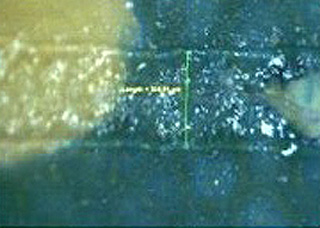

Removal of TCO on CIGS + Mo Glass

Wavelength : 1064nm

Removal of CIGS on Mo+Glass

Wavelength : 1064nm

Pulse energy :

Rep rate : 500kHz

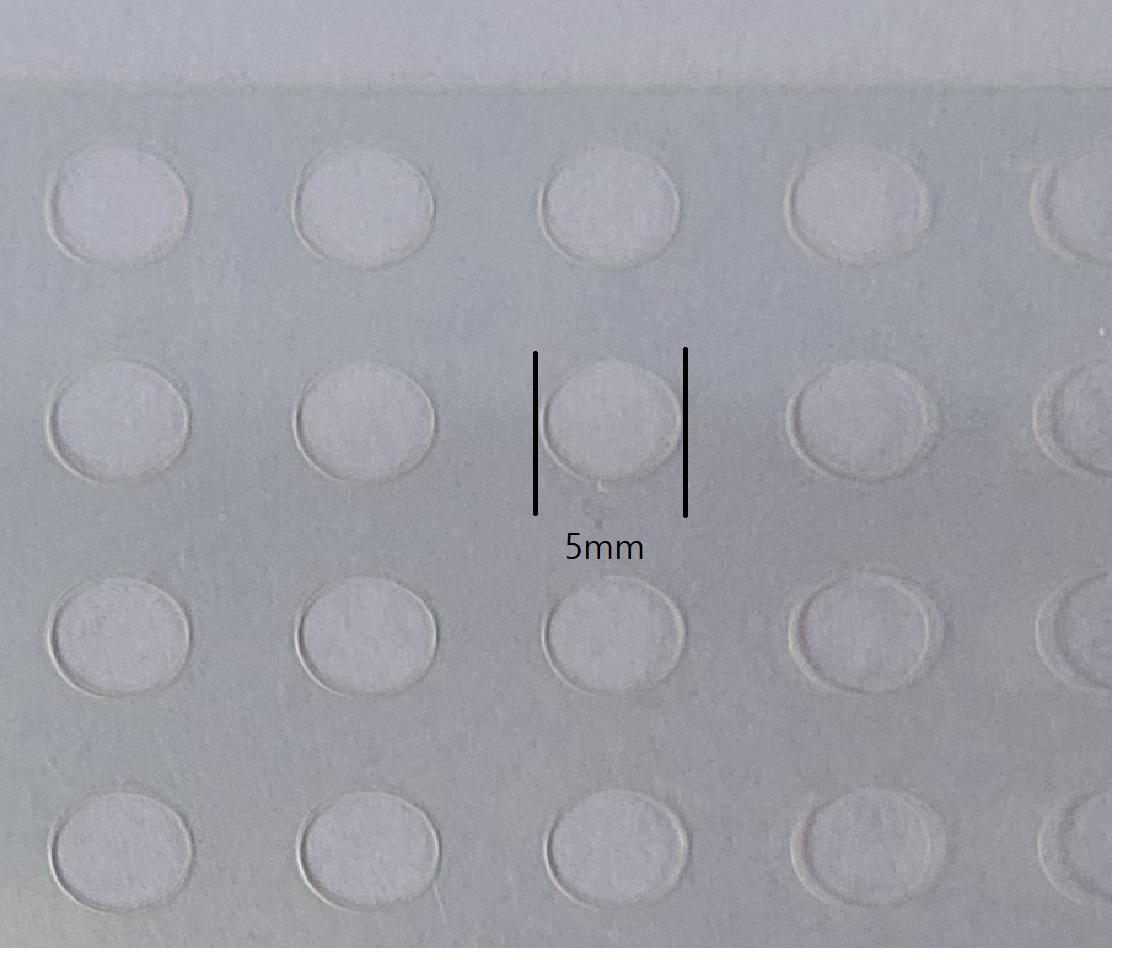

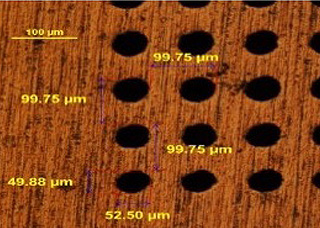

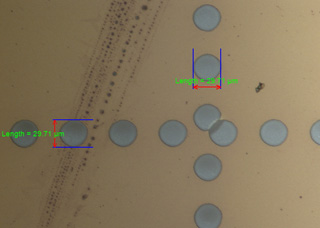

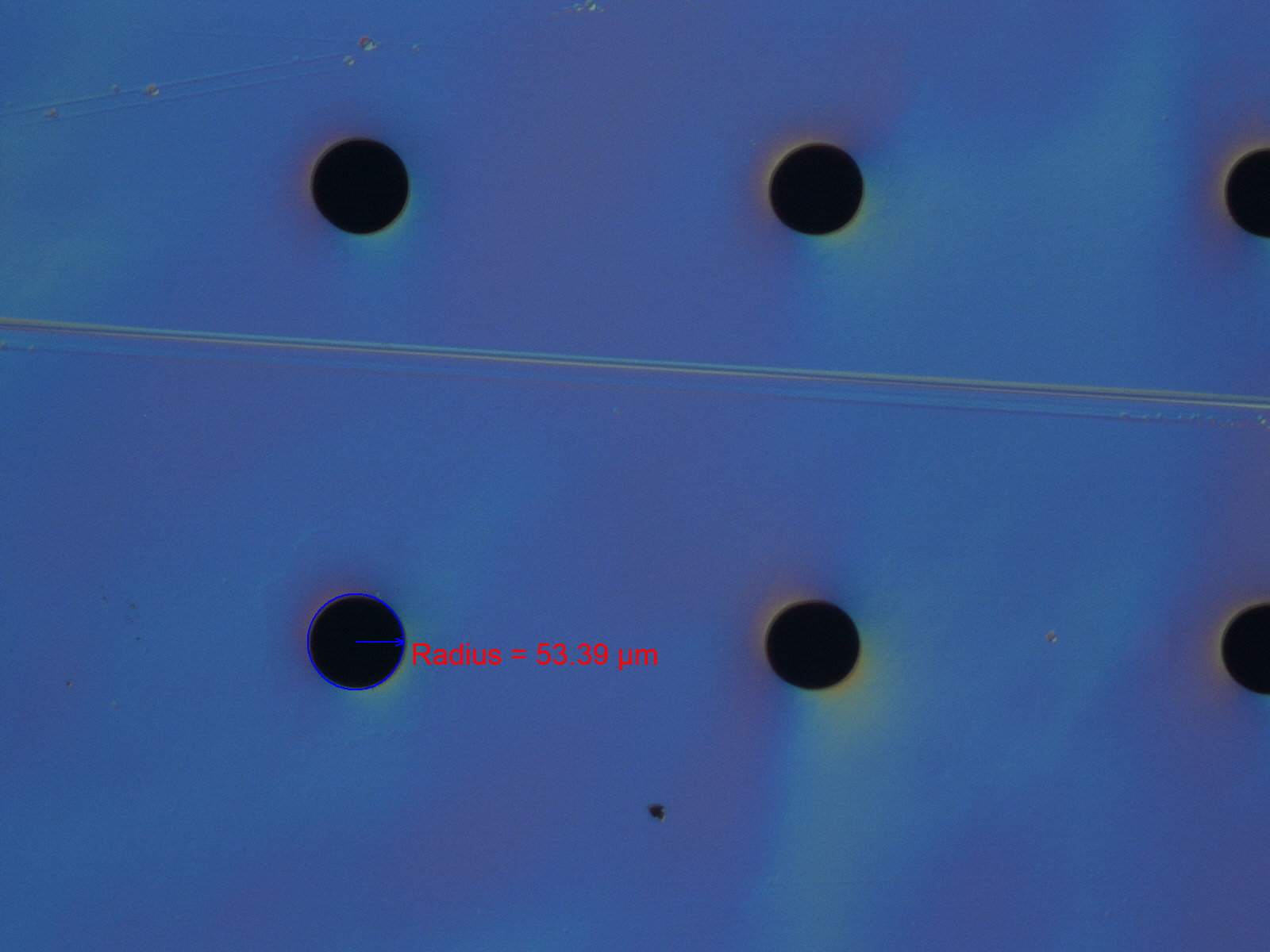

Silicone Sheet Hole Drilling

Wavelength : 355nm

Si Wafer Pattern Cutting

Wavelength : 532nm

Si Wafer Pattern Cutting

Wavelength : 532nm

Si wafer Drilling

Wavelength : 532nm

Si Wafer Align Key Marking

Wavelength : 355nm

Si Wafer Circle Cutting

Wavelength : 355nm

Thickness : 700μm

Si Wafer Pattern Cutting

Wavelength : 355nm

Ceramics

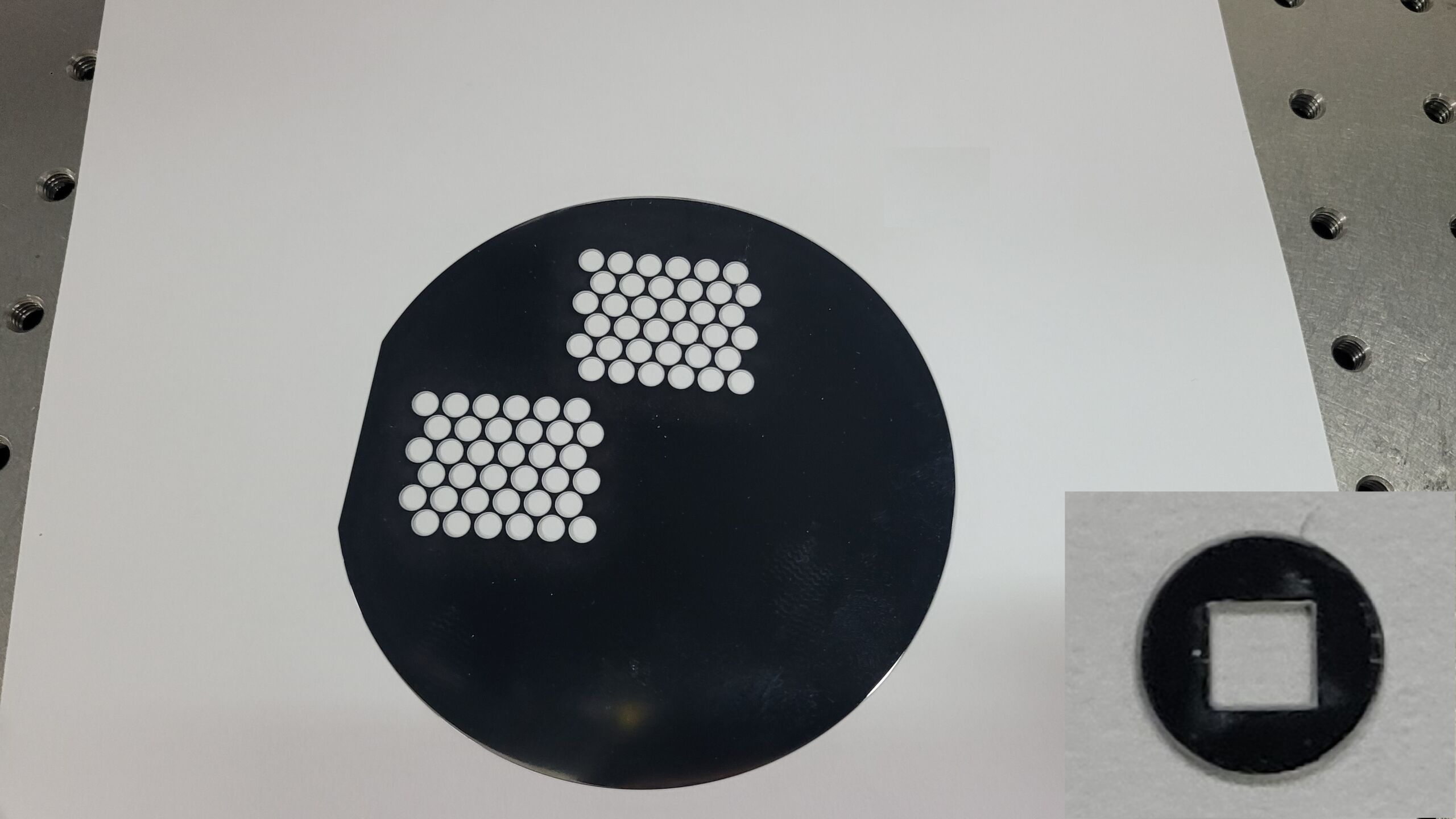

AIN Wafer Hole Drilling

Wavelength : 355nm

Ceramic Hole

Wavelength : 10.6μm

Ceramic Pattern Cutting

Wavelength : 532nm

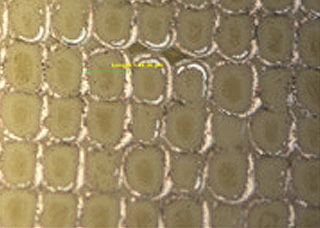

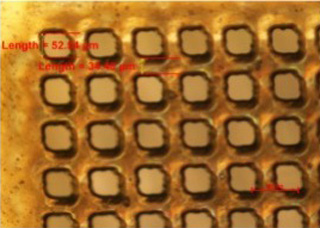

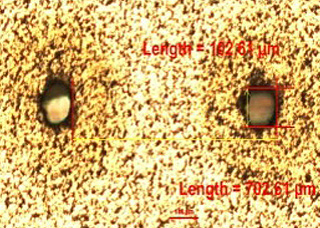

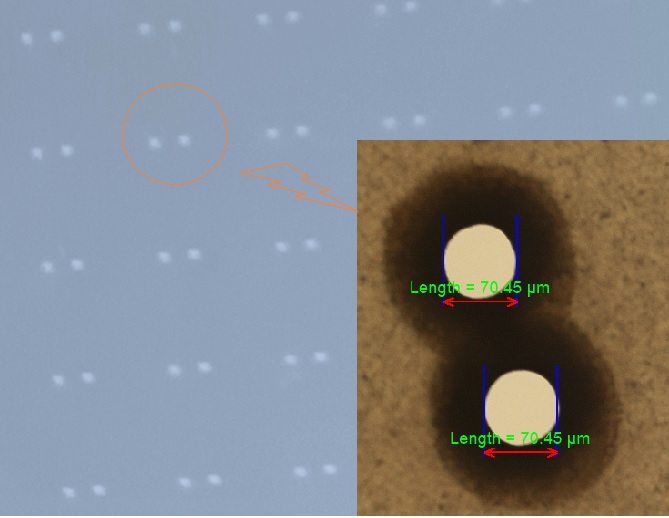

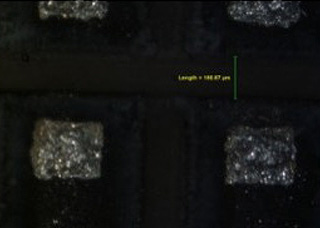

Alumina Via Hole(70μm)

Wavelength : 1064nm

Thickness : 80μm

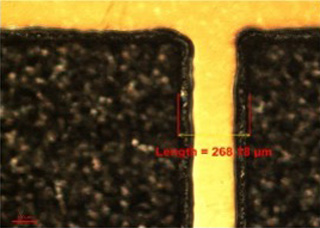

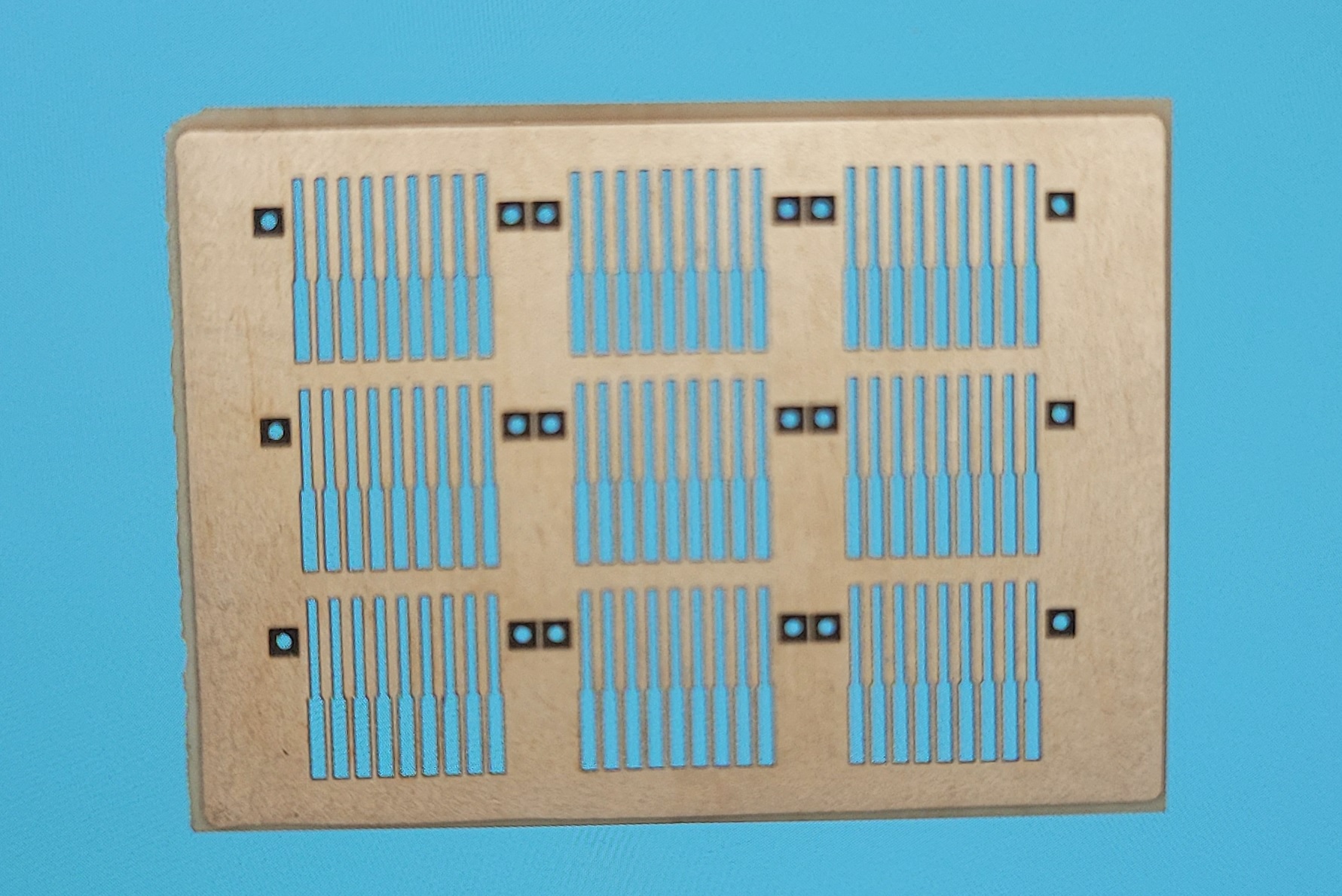

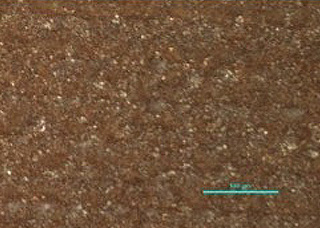

Ceramic Pattern cutting

Wavelength : 355nm

Thickness : 80μm

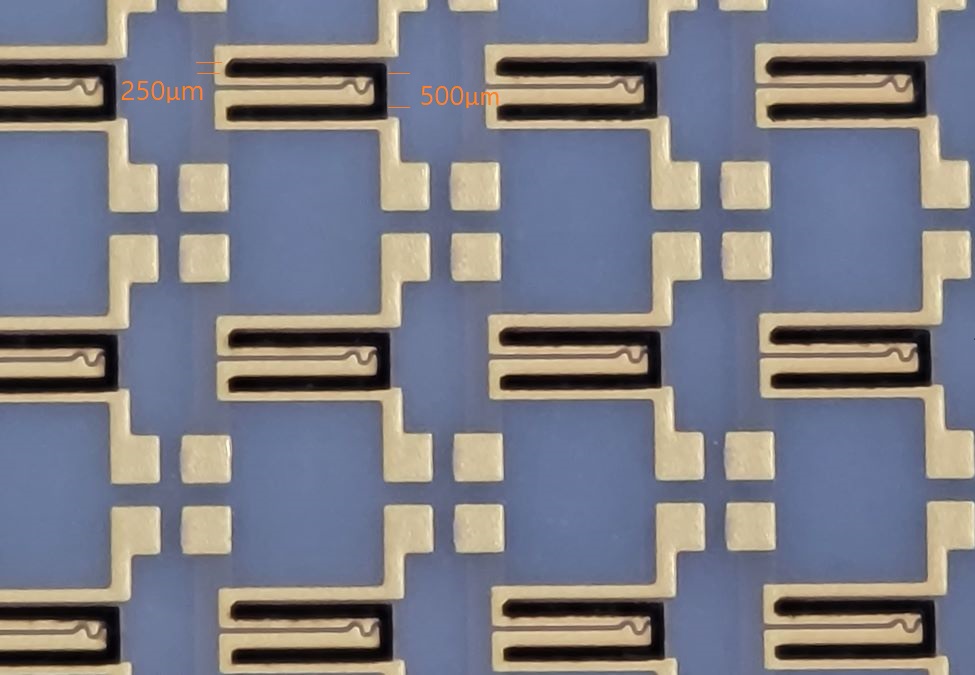

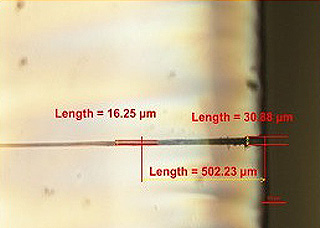

Ceramic Pattern cutting

Wavelength : 355nm(Pico seconds UV)

Thickness : 160μm

Metal

Au Pad Full Scribing

Wavelength : 355nm

Copper Foil Hole Drilling

Wavelength : 532nm

Back Electrode Film Ablation (ZnO on the Glass)

Wavelength : 355nm

Ag Nano Wire Thin-film Scribing

Wavelength : 1064nm

Cu Hole Drilling

Wavelength : 355nm

Thickness : 0.1mm

SUS Hole Drilling

Wavelength : 355nm

Thickness : 0.1mm

Alumina Tube Hole Drilling

Wavelength : 10.6μm

Metal Film Patterning

Wavelength : 355nm

SUS304 Hole Drilling

Wavelength : 355nm

Aluminium Through Line Patterning

Wavelength : 532nm

Metal Oxide Film Ablation

Wavelength : 532nm

Si Wafer Metal Layer Ablation

Wavelength : 355nm

Transparent Materials & Etc.

Quartz Micro-Hole Drilling (Cross-Section)

Wavelength : 355nm

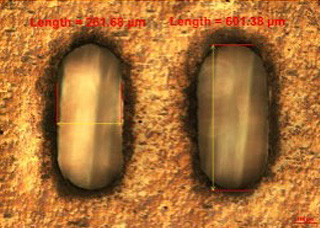

Sapphire Micro-Hole Drilling

Wavelength : 355nm

Thickness : 420μm

Soda-Lime Glass Hole Scribing (Via Hole)

Wavelength : 355nm

Quartz Hole Patterning (Via Hole)

Wavelength : 355nm

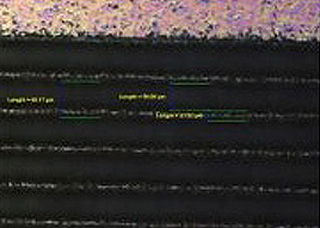

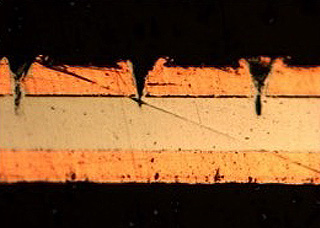

Superconductor GdBCO Thin Film Scribing (Cross-Section)

Wavelength : 355nm

Superconductor GdBCO Thin Film Hole Drilling (Through Hole)

Wavelength : 355nm

Quartz Scribing

Wavelength : 10.6μm

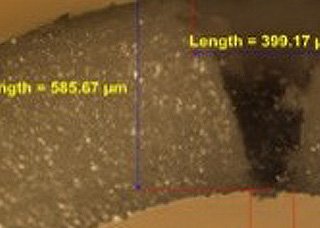

Flexible Gorilla Glass Cutting

Wavelength : 355nm

Slide Glass Cutting

Wavelength : 355nm

Glass & Medical

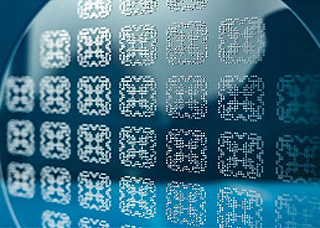

Borosilicate Glass 3.3(Dia 6", 웨이퍼)

Thickness: 1mm

Laser : Femto seconds 1030nm

High precision glass drilling

High precision glass drilling

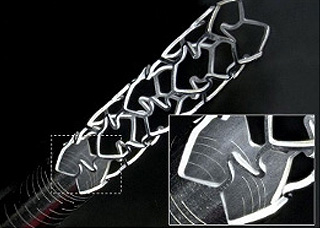

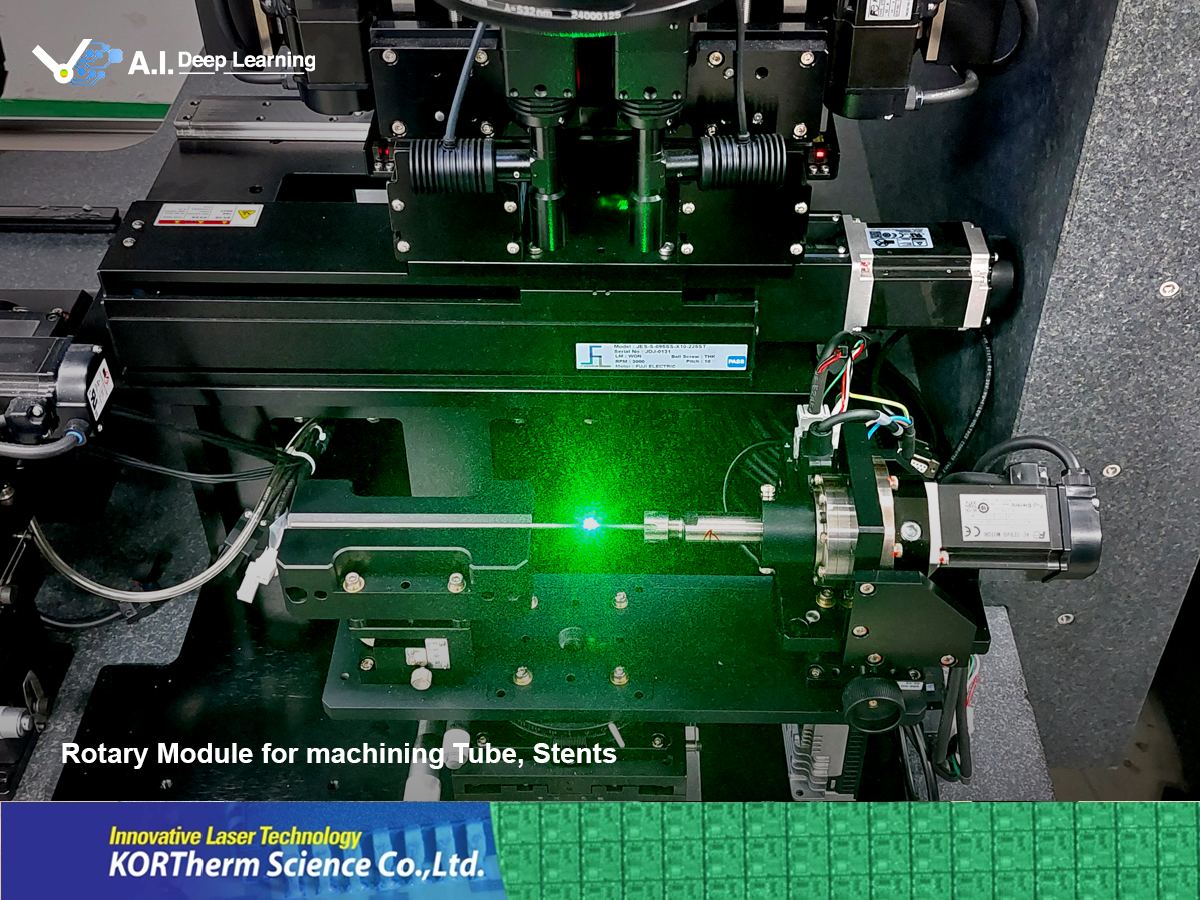

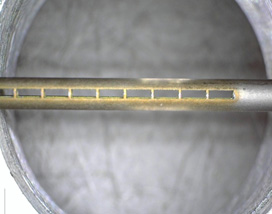

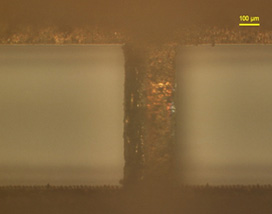

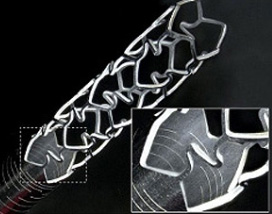

Stainless steel stent cutting

ITO Glass Top side Results

Wavelengh : 532nm

Top hat beam with pi shaper results

Modification Inside Glass

Wavelengh : 1064nm

Thickness : 500um

Borosilicate Glass(Bessel beam)

Wavelengh : 1030nm

Thickness : 1mm

Glass 기판

Wavelengh : Femto seconds 532nm

Thickness : 600μm

Etched TGV Substrate (D263)

Wavelengh : 1064nm

Thickness : 500um

Modification TGV Substrate (D263)

Wavelengh : 1064nm

Thickness : 500um

TGV Substrate - Hour Glass Shape

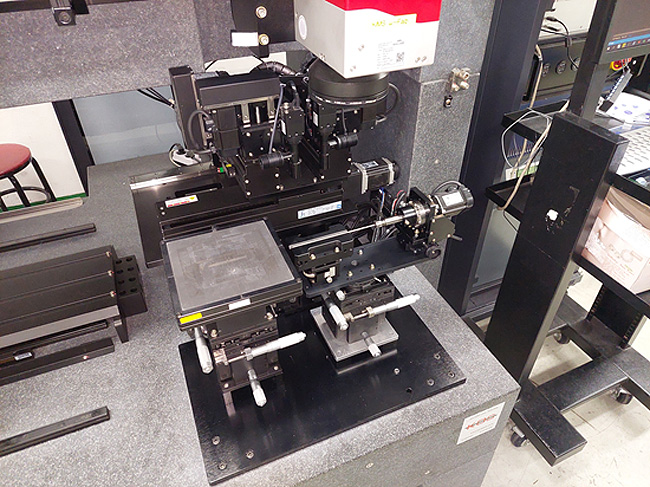

Pipe 가공 가능 Jig 구축

대면적 CO₂

Epoxy Resin Patterning

Thickness : 355nm

기타

Graphene Cutting

Wavelength : 355nm

Carbon Disk Hole Drilling (100% Carbon)

Wavelength : 355nm